5 Inventory KPIs every merchant should know

Understand these 5 KPI and see how you can improve your businessManaging inventory is a complex business. Lots of activities, processes and people are involved in ordering, receiving, storing, picking and shipping items with the ultimate aim of keeping customers happy with complete orders that are on time.

Inventory management KPIs are essential as they help analyze and track the performance of inventory management activities and eliminate guesswork, e.g. how stock is ordered, managed and turned.

With a range of inventory management data, you can measure the progress of supply chain objectives and identify areas for improvement so you can make strategic, data-led decisions.

Table of Contents

What stock management KPIs should you track?

Every business is different and will be working toward different targets, but here are some tips for selecting the best ones for you:

- Choose KPIs that will bring value and helpful information on improving your inventory management effectiveness.

-

Think about your strategic business objectives and choose KPIs that will support them.

For example, improving cash flow, customer service targets, growth strategies or profitability objectives. If you’re planning your objectives, think about what information you’re missing and what questions your board might ask so you can provide the answers.

-

Don’t just focus on your internal environment.

Think about your customers and their satisfaction levels so you can ensure their return business.

- Consider whether your inventory management systems have the functionality to provide these KPIs or whether you need to upgrade or invest in additional software.

KPIs will influence how employees carry out their jobs, so ensure the metrics you choose will promote the right collaborative behavior and avoid any that encourage competition between departments.

Don’t forget that once your KPIs are in place, you need to track and communicate regularly across your business. Your business or inventory management system should be able to help with this. Employees need to understand their importance and how they’ve individually impacted performance. Offer praise when you’re performing well and constructive feedback when performance needs to improve to keep everyone motivated towards the same goal.

5 Important Inventory KPI's

The metric can be used across a lot of different areas of your business, here are some examples:

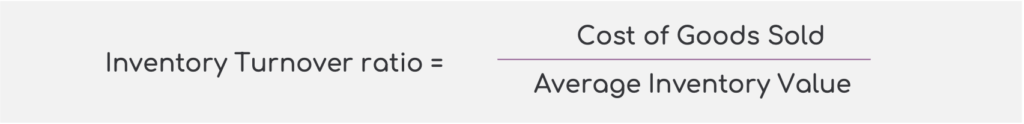

1. Inventory Turnover Ratio

Inventory turnover ratio measures how quickly stock is sold and replaced (turned over) in a predefined period – usually a year.

The most common way to calculate Inventory Turnover Ratio is as follows:

In this formula, the Average Inventory Value calculation is as follows:

Inventory turnover is a good indicator of the efficiency of your inventory management processes.

A higher turnover generally means greater efficiency. However, be careful not to simply lower inventory levels across the whole warehouse to improve your turnover rate, as this could be at the expense of order fulfilment. Read our eGuide on How to fix inventory turnover challenges for more tips.

Inventory turnover is a good indicator of the efficiency of your inventory management processes.

A higher turnover generally means greater efficiency. However, be careful not to simply lower inventory levels across the whole warehouse to improve your turnover rate, as this could be at the expense of order fulfilment.

Read our Merchant Support user guides on How to review inventory turnover challenges for more tips.

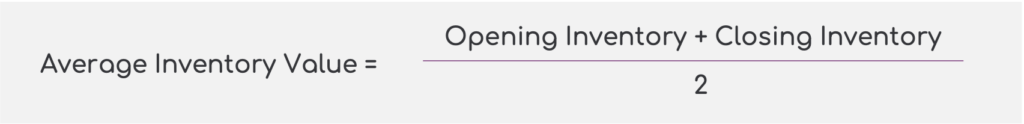

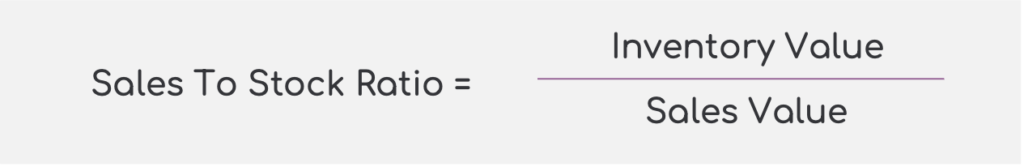

2. Sales To Stock Ratio

The stock-to-sales ratio compares how much inventory you have available to sell versus what you have already sold to check the health of your stock levels.

You can use this ratio to adjust your stock levels so they are continuously optimised to reduce holding costs, improve cash flow, maintain high margins and reduce the possibility of stock-outs.

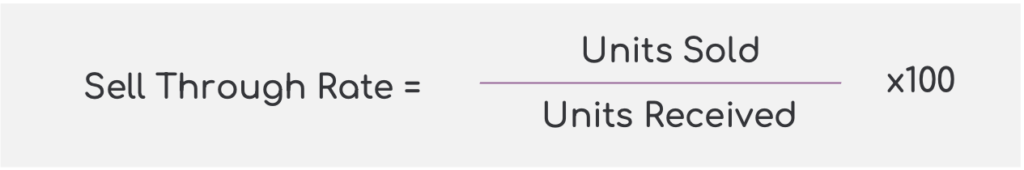

3. Sell Through Rate

The sell-through rate compares the total inventory sold with the total inventory received from a supplier.

This can help you understand your demand forecasting accuracy (something the team at Shelf Planner will keep an eye on for you), highlight popular products, and mitigate storage costs, which all help you understand supply chain efficiency.

4. Cost of Goods Sold (COGS)

Cost of goods sold directly impacts your profitability. Your revenue minus the COGS is equal to your gross profit. That’s why getting the right picture of your cost of goods sold is critical for the overall health of your business.

Higher COGS with disproportionate pricing can leave your business in a deficit position if the prices are too low or alienate consumers if the price is too high.

5. Carrying Cost of Inventory

Inventory carrying costs or holding costs, include all the overheads (many hidden) you incur by stocking items in your warehouse.

These costs include:

- Capital costs – all costs related to the investment in buying stock, e.g. the cost of the stock, the interest on working capital and the opportunity cost of the money invested.

- Inventory service costs – these include insurance, security, IT hardware and the cost of physically handling the goods.

- Storage space costs – a combination of the warehouse rent or mortgage and maintenance costs, such as lighting, heating and air conditioning.

- Inventory risk costs – costs that cover the risk of items losing value while stored, shrinkage, or becoming obsolete.

The carrying cost of inventory is calculated by totalling the above overheads and dividing by the average annual inventory cost. Holding costs are expressed as percentages; values typically range from 15-20%.

You can improve this KPI with more efficient warehouse and inventory management processes.

If you can keep goods moving through your warehouse and avoid excess inventory and obsolete stock, your carrying cost KPI will be in good shape.

KPI's that will optimize your stock levels

There are many KPIs that you can use to analyse your stock management efficiency. In this article, we’ve discussed 5 that we see most commonly used. However, ensure you choose the ones that best suit your business needs so you’re tracking useful information that can help you improve your inventory management processes and efficiencies.

At Shelf Planner, we believe the most important inventory KPIs show how well you’re optimizing your stock levels. Why? Because stockouts and, adversely, excess stock cause a wealth of problems for businesses, from financial concerns to marketing catastrophes.

Inventory optimisation KPIs focus your analysis on how well you’re meeting demand whilst managing stock levels to prevent over- and under-stocking. We delve further into key inventory management KPIs and how to use them in the app in our User Guides.

To improve this number (or make it easier to manage), use an inventory tracking system to track your inventory levels and sales orders in near real time.

How can Shelf Planner help?

It’s a proactive tool that helps you avoid:

- Stock Outs

- Excess inventory

- Lost Sales

- Disappointed customers

This is done by using inventory management tools that track stock levels in real time across all your sales channels. That way, you always have an accurate picture of your stock levels and you can make informed decisions about restocking.

Automated inventory management with Shelf Planner

Shelf Planner’s AI-based inventory management platform supports you with all the tools you need to optimise your business.