So you messed up Black Friday…again…

So What Went Wrong?

Any holiday is a stress tests for any supply chain, and Black Friday is certainly the toughest of all. It is more challenging to get it right than to get it wrong, particularly in these times of severe supply chain interruptions.

Last year, consumers were prepared to spend in the weeks leading up to Black Friday, but businesses in the fashion and cosmetics industries struggled to stock their shelves due to problems in the global supply chain. The opposite is true this year.

Many shops now have an abundance of inventory as a result of shipping delays and over-ordering. Consumer spending is uncertain in the meanwhile due to the oil crisis in Europe, rising prices, and the possibility of a recession. As a result, this year’s Black Friday markdowns have been early and aggressive as merchants try to get rid of stock.

However, let’s suppose for a moment that your supply chain was unaffected. This might be the case if you manufacture on site, source locally, or if there is no shortage of your raw materials. Lucky you, if that’s the case! Although you were able to order and stock exactly how you wanted, when the big day finally arrived and passed, everything looked drastically different than you had anticipated. Now what?

You Ran Out of Stock…

Anyone new to inventory management and demand forecasting may believe there is nothing more relaxing than sitting on a stack of empty pallets in front of a vacant warehouse and watching the final few customers leave the parking lot. Selling out is generally a nice problem to have, perhaps, with the exception of that nagging thought in the back of your mind – “Could we have sold more?”

Which brings up the following dilemma: Which is preferable, having no stock left, or keep some safety for future sales? Although “zero” may automatically come to mind, that is not always the case:

If you don’t have any stock left at all, you might have been spot-on, but can you ever be sure? If they had been in stock, there’s a good chance you would have sold ten more. Maybe you could have sold an additional hundred. With no stock remaining, you just don’t know; with one left, you have a certain outcome.

If ifs and buts were candy and nuts we’d all have a merry Christmas… The only way to get an idea of which items to mark down, or to understand how much stock to keep is to apply short term forecasting . This will help you to better understand your demand for the weeks to come and allows you to buy the right volumes at the right time, but also signals when to stop buying.

You bought too much, and now you’re sitting on too much inventory…

Unless you’re in the business of selling freshly baked goods like cookies or other perishables, having too much inventory might be ok because you can always sell it later. However, nobody is delighted when things are just sitting there in the warehouse. Enter the fire sale, which may be as predictable in certain locations as the Tuesday after a Monday. It is obvious that all of these “50% OFF” bargains reduce your profit margin and may even wipe out any gains from Black Friday.

If you’re not resting on empty pallets but rather atop boxes upon boxes of goods, take the following into account:

Make sure your inventory costs are accurate, taking into account marginal situations as well as per-SKU expenses as well as worldwide costs. Why does that matter? The majority of businesses use a straightforward, single number to represent the cost of stock-keeping: 0.8% of monthly sales price, 50 cents per kilogram, or some other easily determinable factor that closely corresponds to your situation. Although this makes sense in general, it can be misleading when used to make stock clearance decisions for a variety of reasons.

- Costs associated with stock-keeping are frequently long-term, therefore decreasing stock won’t necessarily result in a linear decrease in warehousing expenses. (For an empty warehouse, you still have to pay rent.)

- Depending on the SKU, the actual savings can vary greatly. A small, pricey product won’t have as much of an influence on cost as a cheap, large one because you may keep the latter in stock for a longer period of time without incurring substantial additional costs.

- In general, you should concentrate on the working capital component of your inventory. Your excess inventory is a great source of liquidity if you’re short on cash. But don’t overpay for that money! There might be more effective ways to obtain that liquidity than emptying your warehouse, given how low interest rates are currently.

Everything ultimately boils down to choosing the right discount. Make the ideal adjustments for each product to capitalize to the fullest on customer price sensitivity. That is what the Shelf Planner Price Optimisation Module accomplishes. It’s possible that you’re not sure as to whether to set the discount for a specific SKU as “20% OFF” or “30% OFF”.

The Price Optimisation Module will inform you, for instance, that the exact sweet spot, where increasing volume and lower margins result in the maximum profits, is at 18% off. Additionally, you don’t need to manually maintain any of that thanks to our multiple connectors. Review the offered discounts in the Pricing Module, and with a single click, you can immediately implement them in your online store.

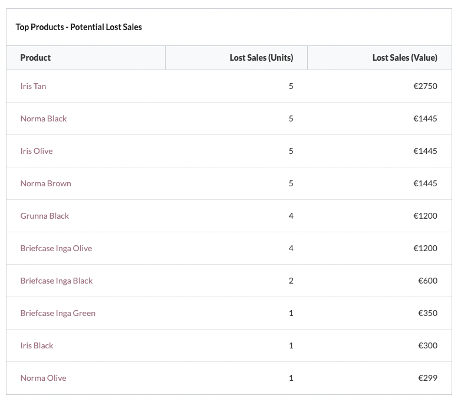

You sold out on some items, but you’re overstocked on others…

If that is the case, it is likely that your planning or business information, either in terms of SKUs or locations, is not detailed enough. You might have stated, “Since our volumes increased 20% on Black Friday last year, let’s order 20% more of everything.” You don’t require any such simplifications with Shelf Planner’s Demand Forecasting Module because the platform forecasts at the SKU level. The platform serves as your buyer’s assistant, trusted with the crucial activities that must be completed but would be a poor use of your time without this minute attention to detail and interaction with your ERP.

Final Thoughts

This year, some of the logistical difficulties from the last year have continued, and industrywide, driving efficiency has taken center stage.

More than ever, supply chains face unique hurdles on Black Friday, and Shelf Planner’s set of forecasting and optimization capabilities makes it possible to maintain control over stock levels and pricing points even in the face of considerable unpredictability.

Furthermore, it does so at a level of granularity that enables you to optimise difficult decisions across thousands of products without having to keep track of every single detail all the time.

Looking for more information about demand forecasting? Why not browse through some of our case studies to learn how we’ve applied demand forecasting to boost stock availability and enhance forecast accuracy. For the most recent articles about AI, visit our Shelf:Life blog. When you’ve satisfied your thirst for information and are prepared to advance your Demand Forecasting approach, contact us here.